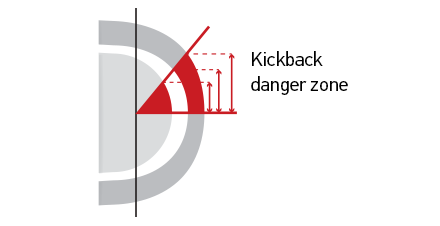

What is ANSI?

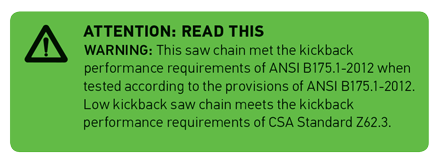

Certain provisions of the safety standard known as "ANSI (American National Standards Institute) B175.1 - Gasoline powered Chainsaws - Safety Requirements," contain requirements designed to reduce the risk of injury from chainsaws sold in the United States. The following information should be used as a guide for the selection of appropriate replacement chains in order to maintain compliance with the ANSI B175.1 standard (United States only).The ANSI standard B175.1 divides all chainsaw power heads into two groups:

- Under 3.8 cubic-inch (62cc) engine displacement, the chainsaw MUST meet the low kickback provisions of the standard.

- 3.8 cubic inch (62cc) and larger, the chainsaw MAY OR MAY NOT meet low kickback provisions of the standard.

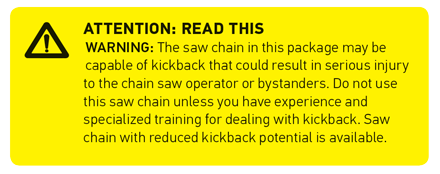

Any chainsaw that does not qualify as a low kickback cutting system will bear a warning such as: “WARNING – This chainsaw is capable of severe kickback that could result in serious injury to the user. Do not operate this chainsaw unless you have extraordinary cutting needs and experience and specialized training for dealing with kickback. Chainsaws with significantly reduced kickback potential are available.”