FAQ

When Should You Perform Square-Ground Filing?

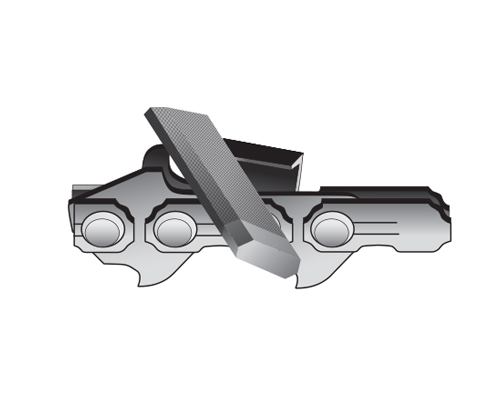

Square-ground filing is typically not necessary for most chain saw operators, as square-ground chain is not commonly used. This type of chain is specifically designed for cutting larger trees with longer guide bars. While square-ground filing can be more challenging and offers less margin for error, the performance benefits of using square-ground chain for cutting timber can outweigh these drawbacks.

Things to Keep in Mind the First Time You File Square-Ground Chain

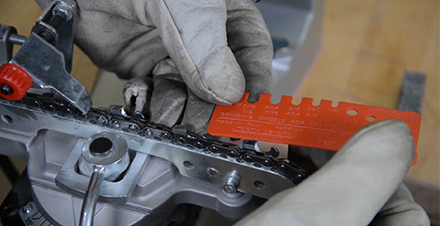

When filing a square-ground chain for the first time, it's best to work in a well-lit and stable environment, such as a shop with a workbench. It's recommended to start with a square-ground chisel chain that still has its factory grind. Do not use an old chain – especially one that has been previously filed as it may still have gullet material attached that needs to be removed.

Tip: Using a second, new square-ground chisel chain as a reference point can be helpful for understanding what the cutter teeth should look like.

Three Rules for Sharpening Square-Ground Chain

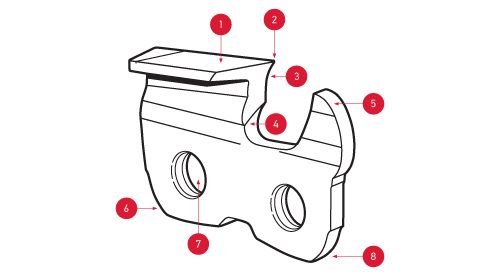

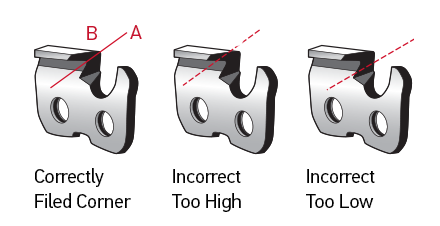

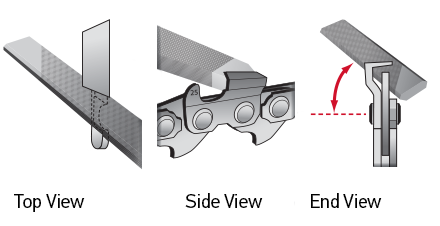

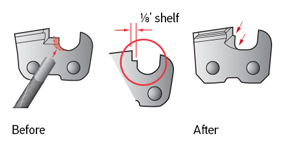

- Keep the corner of the file aligned with the cutter’s tooth

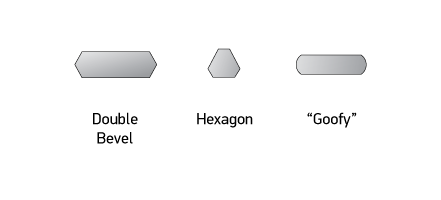

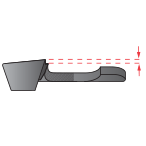

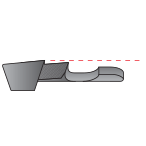

- Maintain the angles of the cutter’s tooth

- Repeat the same angles on every tooth; all cutters need to be the same.