Saw Chain Family Specification Chart — Servicing Dealer

Not all saw chain and guide bar mentioned on the packaging or in search results will fit every version of the equipment listed. To ensure you are getting the correct part, please feel free to call our Customer Service team at 1-800-223-5168.

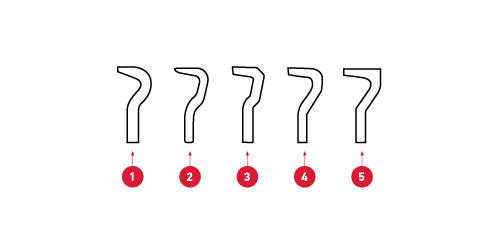

| Saw Chain Pitch | Saw Chain By Gauge | |||

|

|

.043" |

.050" |

.058" |

.063" |

| 1/4" | 25 | |||

| 3/8" Low Profile™ |

90 | 91 | ||

| .325" |

20 95 |

21 | 22 | |

| 3/8" |

72 |

73 | 75 | |

| .404" |

27 59 68 |

|||