Overview

Read on to learn the basics of sharpening your chain with a file or electric grinder, and check out our support videos. There are two main methods you can use for sharpening chainsaw chain by hand with using a round chainsaw file or an electric chainsaw grinder. A third method, square filing, is only meant for square chain used to cut large trees. These instructions are meant to be general guidelines. Refer to your grinder manual for set-up use and instructions. Grind your chain so that it meets the recommendations of the manufacturer. Use a quick tapping motion to minimize overheating of the ground surface.

Before Sharpening a Chainsaw Chain

1. Before you sharpen your chainsaw, you need to know the type of chain and sharpening angle specifications. You can find this information in your chain saw owner’s manual or on the chain pack. The chain identification code is usually written on the driving link. If you don’t know your chain’s type or number, ask your Oregon chain dealer or call our technical services department 800-223-5168. Refer to specifications for sharpening chain with an Electric Grinder or by hand with a Round File.

Questions?

Anatomy of a Chain

1. Top Plate

2. Cutting

3. Corner

4. Slide Plate

5. Depth

6. Gauge

7. Gullet

8. Toe

9. Heel

10. Rivet Hole

11. Clearance Angle

12. Depth Gauge

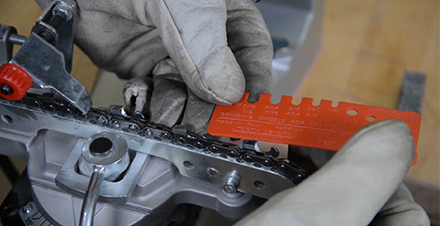

Tool Tip

Before you install a new or used grinding wheel, always perform a "ring test"to check for wheel integrity. A dull thud may indicate that the wheel is cracked and should not be used.

How To Sharpen Chainsaw Chain

Oregon's Senior Technical Services Expert, Glenn, teaches how to sharpen a chainsaw chain. Chainsaw sharpening and chainsaw filing is very important to the health of a saw chain and bar system. To properly sharpen chainsaw chain you will need: a file guide, flat file, and tools to set chainsaw chain depth gauges (rakers and drags).

Saw Chain Anatomy

Oregon's Senior Technical Services Expert, Glenn, explains chainsaw chain anatomy. He will discuss the drive links, tie straps, rivets, cutters, depth gauge (rakers or drags), side plate, top plate, gullet, and overall relationship between all the components of the saw chain. He will share how to identify end of life of saw chain and various versions.

What You Should Do After Sharpening a Chainsaw Chain

1

2