Minimizing the Risk of a Chain Shot Event

For maximum protection, machines should be equipped with the appropriate safety attachments. Please follow the recommendations below and reference your equipment’s operator manual.Guards and Shields

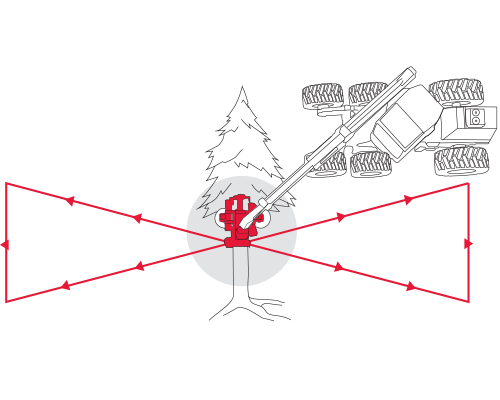

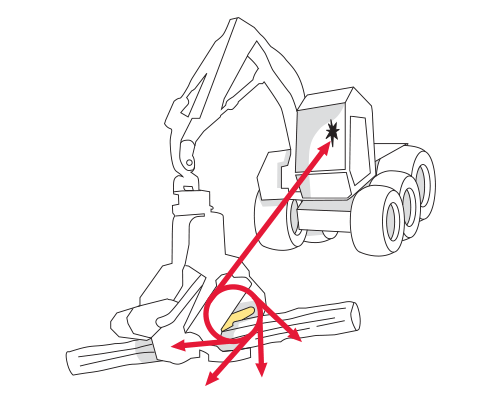

Because of the high speeds, high stress, heavy loads, wear factors, and varying levels of repair and maintenance given to saw chain-based mechanized wood harvesters/processors, there is a possibility that saw chain or saw chain pieces can be thrown from the machine at high speed and velocity. Machine operators, ground personnel, and bystanders are exposed to a risk of serious injury or death. Equipment should be equipped with appropriate guards, shields, and window enclosures to minimize the exposure of the operator, ground personnel, and bystanders to the cutting plane and Shot Cone Zone of the cutting system. Bystanders and ground personnel should be kept at least 230 feet way.

Windows

- The glazing of the operator's enclosure window should comply with local codes for impact resistance. The glazing should be replaced if any scratches (or other damage) obstructs the operator's effective viewing of the cutting operation.

- It should be noted that the UV portion of the light spectrum degrades the properties of polycarbonates and its ability to withstand impact is diminished. Consult your equipment manufacturer or replacement glazing supplier for recommended replacement interval.

- Before upgrading, always check with your equipment manufacturer as it may change the operational integrity of the operator enclosure.

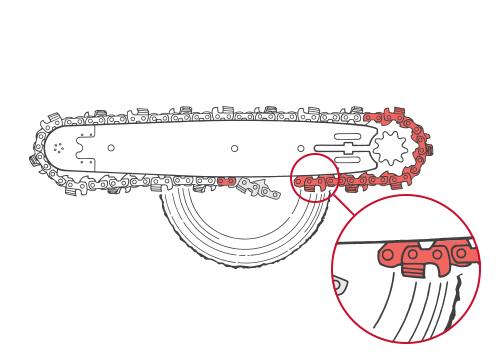

Chain Catcher

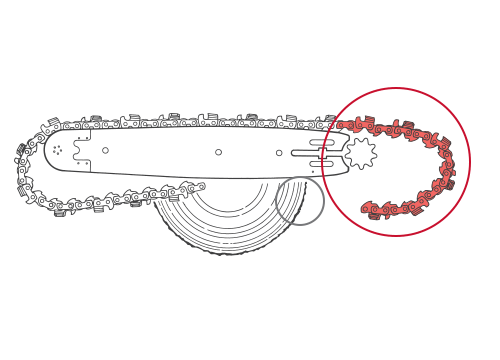

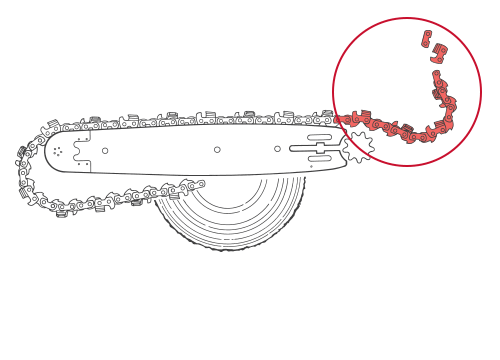

Chain Shot Guard

- Absorbs the energy of a broken saw chain coming in contact with the saw box, and is designed to prevent saw chain parts from breaking off and being ejected.

- Acts as an extension of the saw box, designed to reduce the opportunity for thrown saw chain or saw chain parts to escape the saw box.

Chain Speed, Feed Force, Service Life and Safety